MEASURING INSTRUMENTS

Measuring instruments are the backbone of metrology, and CNC machining is the technique that ensures their perfection. From the creation to the machining of each component, CNC machining contributes to the precision and reliability of measurement instruments in the industry.

The Measuring instruments are crucial in the industry to ensure accuracy and quality in component manufacturing. However, to achieve precise and reliable measurements, it is essential to have state-of-the-art facilities that support this process. This is where the Trevisan Machining Center plays a crucial role. By enabling the production of precise components with the latest technology, this center of excellence significantly contributes to the efficiency and reliability of measurement processes.

Throughout history, various measuring instruments have been developed, which, thanks to technological advancements, can now provide accurate and reliable measurements.

In the industrial context, precision is an essential characteristic that determines the reliability of measurement and control instruments. This quality is reflected in an instrument’s ability to deliver consistent and repeatable results, even under the same conditions in multiple measurements. In a precision-critical environment, such as manufacturing and quality control, an accurate instrument ensures measurement uniformity and consistency, allowing companies to maintain high-quality standards in their products and processes. Precision not only ensures reliable measurements but also contributes to efficiency, waste reduction, and ultimately meets customer expectations in industrial production.

There are two methods to make measurements:

- The direct measurement

- The indirect measurement

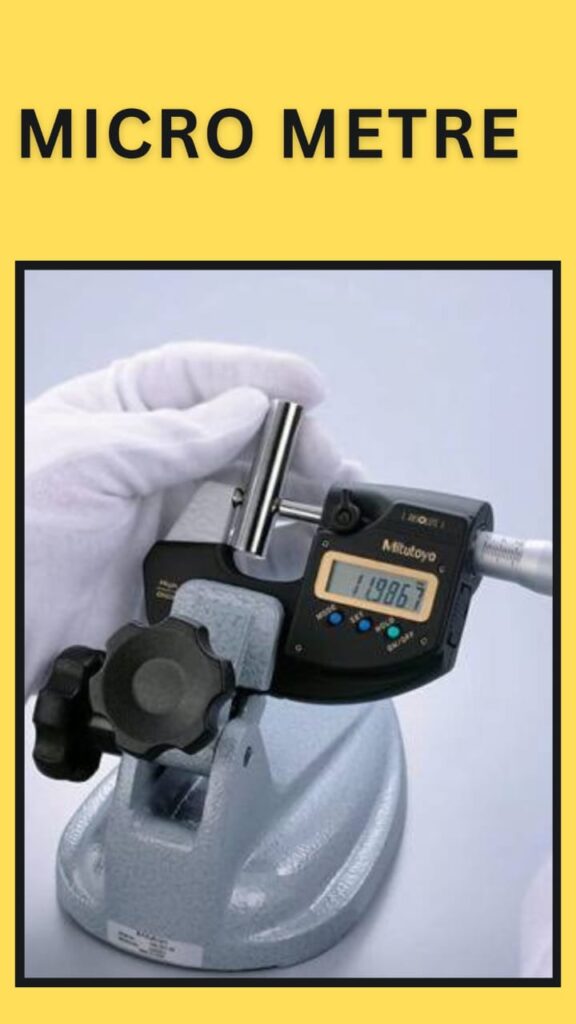

In direct measurement, measuring devices such as gauges, micrometres and coordinate measuring machines are used to directly measure the size of an object. Measurements can be made within a wide range determined by the scale of the measuring device, but there is also the possibility that the measurement is incorrect due to incorrect readings on the scale.

In indirect measurement, dimensions are measured with measuring devices, such as spheres, that observe the difference between reference objects and devices, such as measuring blocks and measuring rings. They are also called reference measures because the comparison is made with an object of standard dimensions. The more predetermined the shape and dimensions of the reference device, the easier the measurement will be.

However, this method also has a limited measuring range. It is slow and laborious for the measurement of few parts and cost effective for the measurement of many.